PRODUCT

BHT 1650FC/1900FC/2100FC

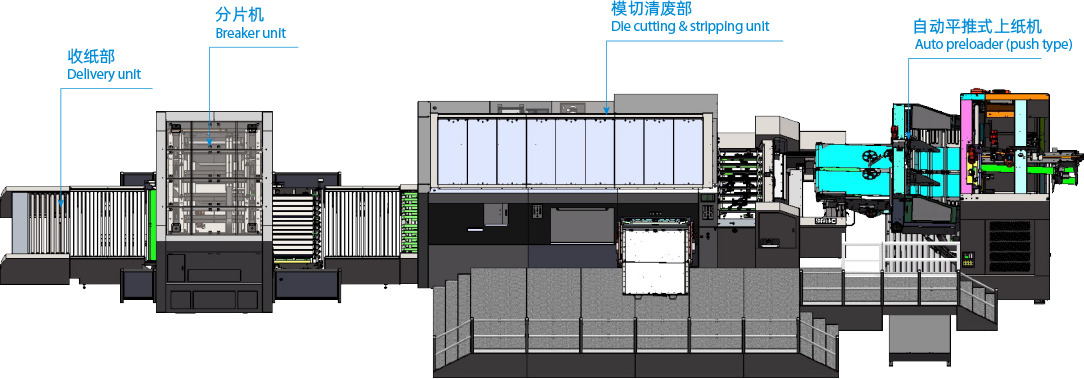

Automatic Die Cutting Machine Linkage Production Line (Lead Edge Feeder)

Features Introduced

Converting System Integration means devices combined in line to reduce the manual work, optimize and speed up the flow of products within a single process. Among different modes of production lines, it is the most popular and practical mode in the global market with higher stability. In this system, the automatic prefeeder is one important part linked with the feeder of automatic diecutter to raise feeding efficiency and relieve the workload of operator at maximum that manual work cannot totally reach. The automatic breaker in line with the delivery unit of diecutter automatically separates blanks from multiple ups and save considerable labor costs compared to manual work. Along with the advantages in efficiency and cost, the system is especially able to be customized at particular client demands, products techniques and processes. Nowadays this sytem has become the new tendency interested by a large number of brand owners in the corrugated board packaging industry.

Partial Introduction

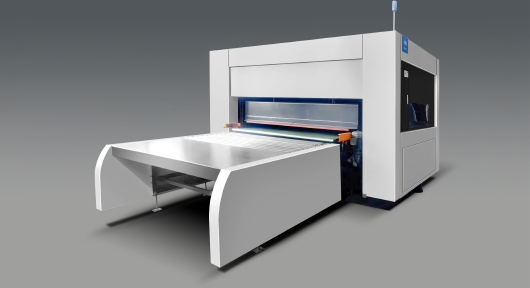

Auto pre-loader

Paper breaker

Main Technical Parameter

Technical parameters of paper feeder

| Model | BHT-2100FC | BHT-1900FC | BHT-1650FC |

| Sheel Size | Max. 2100×1600mm Min. 650×450mm | Max. 1900×1400mm Min. 650×450mm | Max. 1650×1200mm Min. 650×450mm |

| Corrugated Board. Up To | 1-9mm | 1-9mm | 1-9mm |

| Batch Height | Max. 1800mm | Max. 1800mm | Max. 1800mm |

| Pile Weight | 1400kg | 1200kg | 1000kg |

| Machine Weight | 5000kg | 4500kg | 4000kg |

Technical parameters of die cutting machine

| Model | BHT-2100FC | BHT-1900FC | BHT-1650FC |

| Max. Sheet Size | 2100×1600mm | 1900×1400mm | 1650×1200mm |

| Min. Sheet Size | 750×650mm | 650×500mm | 650×500mm |

| Max. Die Cutting Size | 2080×1580mm | 1880×1380mm | 1630×1180mm |

| Inner Chase Size | 2120×1630mm | 1920×1430mm | 1670×1230mm |

| Stock Range | ≤9mm corrugated paper, F, E, B, C, A and AB corrugated paper | ≤9mm corrugated paper, F, E, B, C, A and AB corrugated paper | ≤9mm corrugated paper, F, E, B, C, A and AB corrugated paper |

| Min. Gripper Waste | 10-18mm | 10-18mm | 10-18mm |

| Min. Gripper Margin | 6-12mm | 6-12mm | 6-12mm |

| Cutting Rule Height | 23.8mm | 23.8mm | 23.8mm |

| Max. Die Cutting Speed | 4000s/h | 5000s/h | 6000s/h |

| Max. Die Cutting Pressure | 450ton | 450ton | 400ton |

| Total Power Required | 47kw | 40kw | 38kw |

| Electrical Power | 380V, 50HZ, 3PH | 380V, 50HZ, 3PH | 380V, 50HZ, 3PH |

| Mobile Lower Platen Adjusting Range | ±1.5mm | ±1.5mm | ±1.5mm |

| Machine Dimension | 14370×6360×2970mm | 13377×6360×2902mm | 11638×5254×2776mm |

| Machine Weight | 51T | 46T | 40T |

Sharding machine technical parameters

| Model | BHT-2100FC | BHT-1900FC | BHT-1650FC |

| Sheel Size | Max. 2100mm, Min. 650mm | Max. 1900mm, Min. 650mm | Max. 1650mm, Min. 650mm |

| Min. Batch Dimension In Machine Direction | 200mm | 200mm | 200mm |

| Max. Batch Thickness | 300mm | 300mm | 300mm |

| Min. Batch Thickness | 20mm | 20mm | 20mm |

| Batch Passage Height From The Floor | 900mm (adjustable) | 900mm (adjustable) | 900mm (adjustable) |

| Machine Weight | 5000kg | 4500kg | 4000kg |

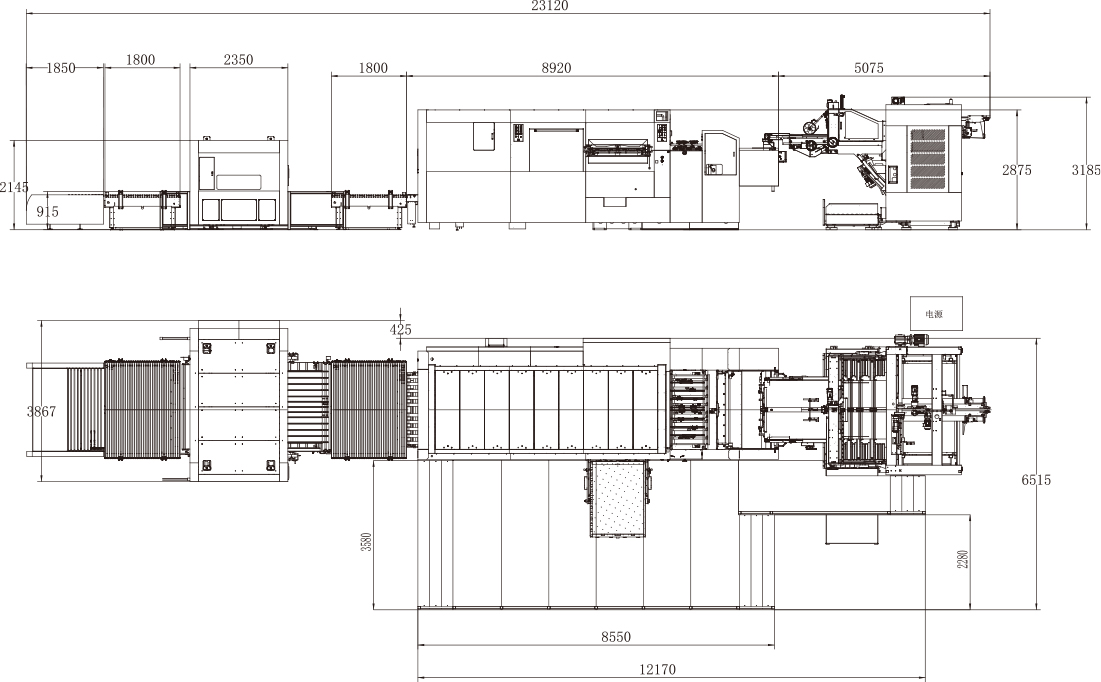

Drawing